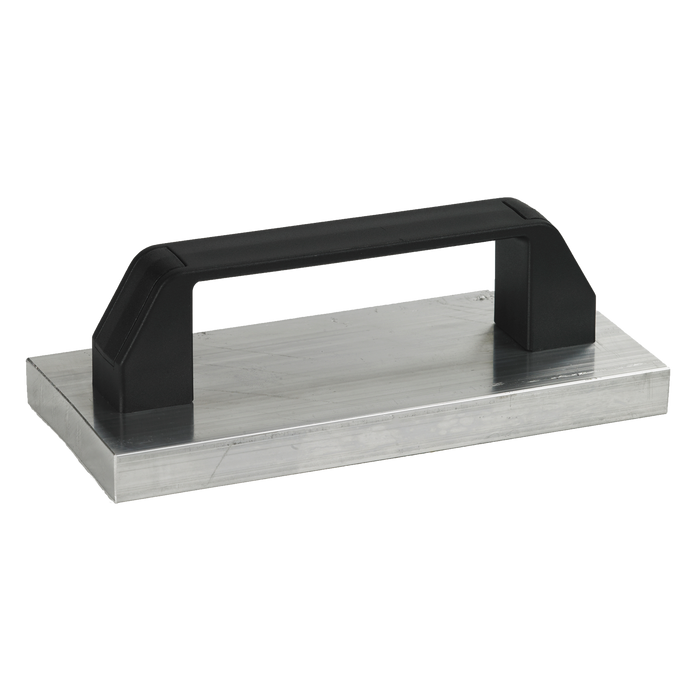

Knot Filler Cooling Iron 80x180mm

Cooling iron w. handle for Knot Filler repairs

This Cooling iron is a perfect tool to have at hand when making wood repairs with Knot Filler. Place the Cooling Iron on top of the warm Knot Filler after it has been shot into the knot/repair. The Cooling iron presses the Knot Filler into the repair and increases the durability of the Knot Filler and quickly cools the repair so it is ready to be cut and sanded.

Product Info:

- Cooling iron in aluminum with a handle in hard plastic

- Size: 80x180mm

- Perfect for bigger and longer repairs

- Useful for repairs in wood and formwork panels

How does it work?

- After Knot Filler application, quickly place the cooling iron on top of the warm Knot Filler

- Do not be afraid of giving it a good push when putting it on

- Leave the Cooling iron on top of the repair and let the Knot Filler repair cool off

- The repair is ready to be cut when the Cooling iron easily comes off

Tip!

- Place cooling irons in line for longer repairs

- Use the Cooling brick 50x50mm in combination with the Cooling iron

VIEW PRODUCT INFORMATION/COLOUR SHEET HERE

Includes:

- 1 x Knot Filler Cooling Iron 80x180mm

Knot Filler Accessories & Kits sold here

INSTRUCTIONAL/DEMONSTRATION VIDEOS:

What kind of repairs is Knot Filler suitable for?

Knot Filler is suitable for all types of softwoods, hardwoods, plywoods and more!

It is perfect for all kinds of repairs such as knots, cracks, edge repairs, corner repairs, cover-up of screws etc. Knot Filler is also perfect for formwork repairs, and it has become a popular repair material in the formwork industry.

Why should I use Knot Filler instead of epoxy?

There are several reasons why Knot Filler is preferable to epoxy:

1) Knot Filler is non-toxic and therefore does not harm neither the environment nor the user

2) Knot Filler is a faster way to repair wood

3) Knot Filler is flexible and works with the wood, thus stays in the wood and does not crack

4) Knot Filler is ready to use - no mixing

5) Knot Filler dries in seconds

6) Knot Filler is UV proof

7) Knot Filler accepts all kinds of surface treatments after sanding

8) Knot Filler is suitable for all kinds of repairs, no real limits to the possibilities of repairs with Knot Filler.

Can I use Knot Filler outside?

Yes. Knot Filler can be used for both internal and external repairs. Knot Filler has been tried & tested in a variety of climates all over the world!

Does Knot Filler accept stain, oil, etc?

Yes. Just be sure to sand the repair first, as this "opens" the repair, so it accepts any kinds of surface treatment.

How do I change colour?

There are a few options to choose from in terms of changing Knot Filler colours. We recommend the following:

1) Use different heating guns for different colours,

2) Use our Knot Filler Saver to make new smaller Knot Filler sticks of the excess Knot Filler before you get the new colour.

Note: we highly recommend that you always try to plan your repairs so you make more repairs with the same colour, and thereby minimize colour change.

Do you have any certifications for Knot Filler?

Yes, Knot Filler complies with the IKEA test specification IOS-MAT-0054, and has been tested for Bisphenol A, Cadmium, Lead, Organotin, and Phthalates CPSC. Hence, Knot Filler is an environmentally friendly product that does not harm the user nor the environment.

Why do I get bubbles in my repair?

There are two possible causes:

1) The working temperature of the heating gun is too high, which causes the Knot Filler to boil and creates bubbles. It is important to follow the recommended temperature which is noted on the labels of the Knot Filler bags, and adjust the temperature if bubbles occur

2) If the Knot Filler sticks have been exposed to air over time, it creates moisture in the Knot Filler sticks, which causes bubbles when you apply the Knot Filler. In order to prevent this, it is extremely important to close the Knot Filler bags tightly after use, as noted on the labels on the bags.

Does Knot Filler sink?

No. Knot Filler does not sink when it is applied correctly. Hence, when you shoot the Knot Filler into the repair, let it cool down for a while, before you cut off the excess part, you will see a perfect repair. One of the big advantages with Knot Filler is that it does not sink over time. Temperature differences can though affect Knot Filler as it affects all other things. Therefore, Knot Filler might expand a bit in warm temperatures, whereas it might shrink a bit in cold temperatures when it is first applied. From our experience, the reaction does mostly occur in large-size repairs and does not occur in standard repairs. Another advantage of Knot Filler is that you can see the result of your repair instantly. It will not change character or sink later on the surface where it’s applied.

Can I sand the repair and what is the best technique?

When you have filled and cut the repair it is ready to be sanded. Sanding the repair is important as it ensures that the repair accepts the surface treatment you wish to use. It does not matter whether it is oil, stain, lacquer, paint - you can use any surface treatment you want, as long as you sand the repair first. The best technique is to sand the wood 90% prior to starting to repair the wood. When you have filled the repair with Knot Filler and cut off excess you finish the last 10% of the sanding process. Make sure to use a good flow when you sand the wood and the repair, in order to let the repair "breathe" while being sanded.

What is the best way to repair a long and deep crack / damage?

1) Sand the wood 90-95% finish before you start to repair with Knot Filler

2) Fill the repair 2/3 with Knot Filler leaving the last 1/3 top without filler until it has dried

3) when the Knot Filler is dry, you fill the last 1/3 of the damage, cools it down with a cooling iron, cut off excess knot filler and sand the repair.

Can Knot Filler be applied by machine?

Yes. Knot Filler in granulate form is perfect for semi- and fully automatic machinery. We have had positive experience with both semi- and full automatic machinery from Wintersteiger, and both types of machinery work perfectly with our Knot Filler and produce beautiful repair results.

Can Knot Filler be used with industrial sanding machines?

Yes. Knot Filler is perfectly suitable for repairs that are sanded with both hand operated sanders & industrial machinery. The best and most professional results with Knot Filler are achieved with industrial sanding machines such as wide-belt sanders, however hand operated sanding machines are also perfect for Knot Filler repairs.