Cutek Oils:

How they Work

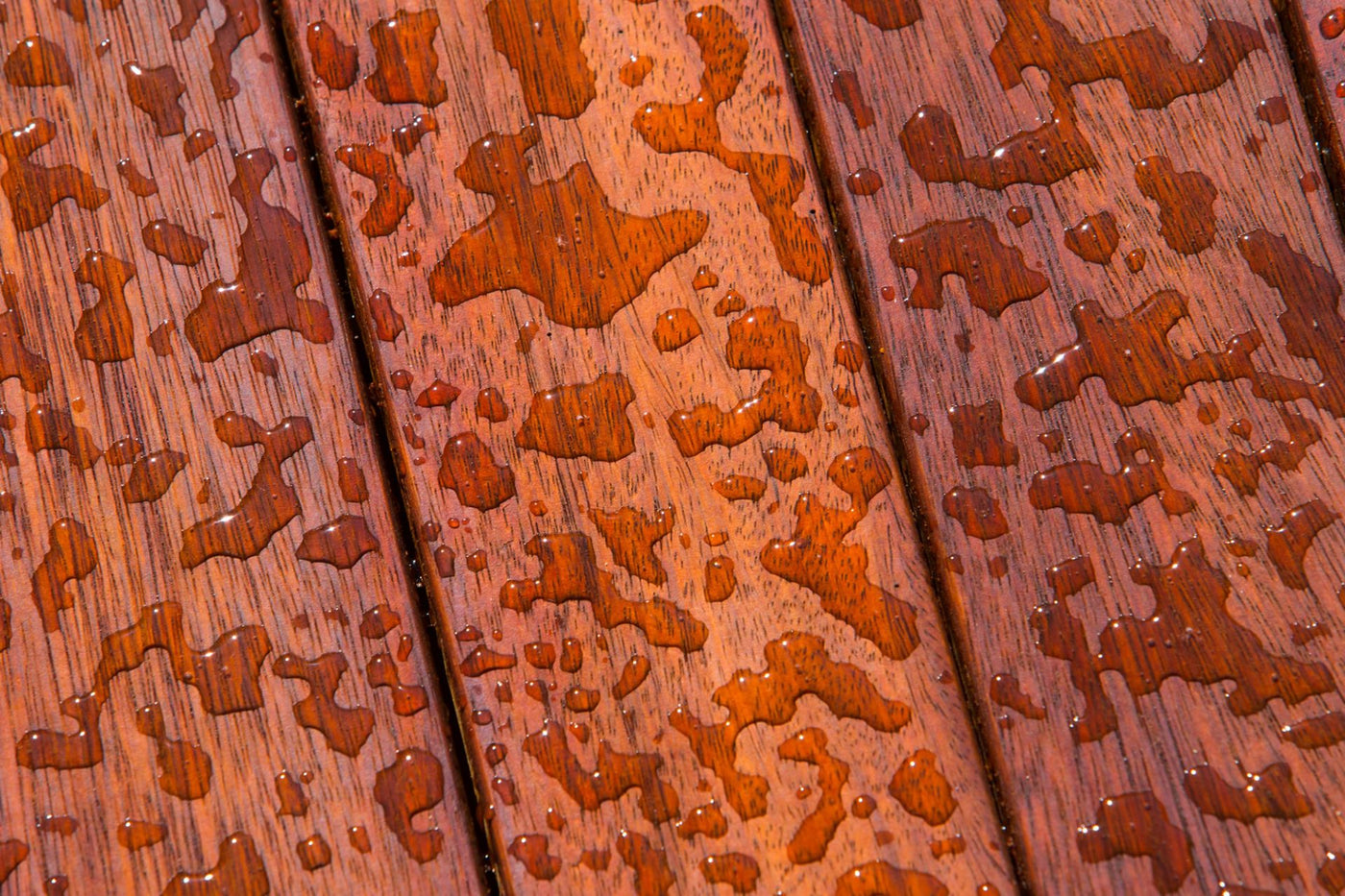

Powerful wood protection

CUTEK® is a powerful wood protection system… but is also so much more than that.

-

-

-

-

Cutek®

Cutek® Extreme CD50 Decking Oil 10L

$34011$37790Unit price /UnavailableLast One Left (1 unit)

Penetrating oil with a self-healing effect

CUTEK® timber oils protect from the inside out by actively displacing water throughout the wood and providing unsurpassed long-term protection against water damage.

The protective components penetrate and stay PERMANENTLY MOBILE in the timber, migrating to any cut or perforation automatically sealing it against the damaging effects of moisture.

It is this mobility and self-healing effect which makes CUTEK® the professional’s choice for long-term timber protection.

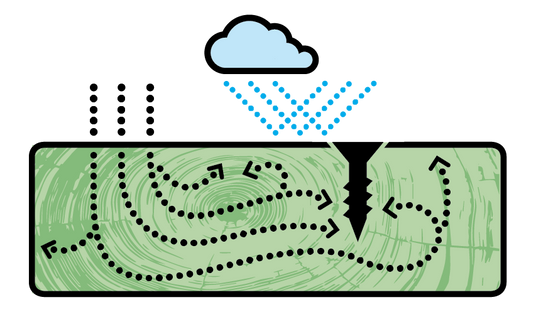

Superior Mode of Action

Traditional varnish and natural oil‘penetrating’ type coatings work by forming a protective film on the surface of the wood to protect against moisture damage.

Over time, UV rays and timber movement break down this film causing it to degrade, flake or peel. This allows water to get into the timber which will leads to cupping, warping, splitting and rot. Rectification is costly and time consuming as the old coating will need to stripped away before reapplying.

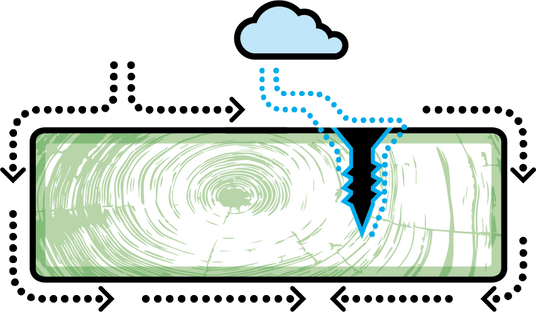

CUTEK® is different. CUTEK® timber oils penetrate deep into the wood core and drive moisture out of the wood from the inside. This offers superior long-term protection and minimises cupping, warping and splitting.

This penetrating oil technology ensures the longest possible service life for your timber. It has been proven to work and has been independently tested by industry experts in many countries over the last 30 years.